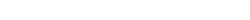

NUMConnect is a communications interface option for NUM CNC systems that allows the CNC to integrate seamlessly with third party manufacturing management software for comprehensive CNC monitoring. With NUMConnect data can be collected from the CNC machine to be stored, organized, and analyzed. Shops can then use this data to create a extensive machine monitoring system that can improve the utilization of their equipment as well as reduce downtime and overall manufacturing cost.

NUMConnect is fully compliant with open source communications protocol – MTConnect. MTConnect is growing rapidly in the machine tool industry and is used to organize the retrieval of data from CNC Machines (click here to learn more about MTConnect).

NUMConnect is fully compliant with open source communications protocol – MTConnect. MTConnect is growing rapidly in the machine tool industry and is used to organize the retrieval of data from CNC Machines (click here to learn more about MTConnect).

MTConnect for CNC Monitoring

The NUMConnect software interface essentially comprises two main components: an MTConnect Adapter and an MTConnect compliant information provider or lightweight webserver known as an ‘Agent’. The Adapter collects data from the CNC system, associates it with defined MTConnect data items, filters out any duplicates and then pushes the data to the Agent, where it is held in a buffer store until overwritten by fresh information. To help minimize response times, MTConnect does not require the establishment of a formal data transfer session, and under normal use there are no log-on or log-off sequences. When the Agent receives a request for information from any client application software, it transfers the appropriate data over the network, using HTTP. The system is inherently secure; MTConnect is a read-only standard designed to facilitate the retrieval of data from manufacturing equipment – it does not control or instruct a CNC machine tool to take action.