Sinumerik 808D/808D Advanced

The Siemens SINUMERIK 808D Low-Cost Control for Milling/Turning is perfect for Knee Mills, Vertical Machining Centers, Routers, Lathes, and Grinders. The control system is suitable for any machine that has 4 interpolating axes. With the 808D Control, servo sizes run from 1.9NM to 40NM. We also provide pre-packaged kits with servo sizes from 4NM to 10NM, which will handle most small to mid-size machines. Our kits are some of the easiest to install and configure on the market.

Sinumerik 828D/828D Analog

The Siemens SINUMERIK 828D Control for Milling/Turning is perfect for Knee/Bed Mills, Boring Mills, Vertical Machining Centers, Routers, VTLs, Lathes, and Grinders. The control system is suitable for any machine that has up to 4 interpolating axes and 10 axes total. The 828D is capable of 3+2 machining using a trunnion table or alike device. With the 828D Control, servo sizes run from 3.5NM to 170NM, which will handle all small to large-size machines. We offer affordable Siemens 828D CNC Retrofit Kits for Knee Mills, Bed Mills, and small VMCs. We also offer a control only upgrade CNC solution that is a fraction of the cost of a full system, reusing the customers drives and motors up to ANY size. Siemens Conversational Programming: ShopMill/ShopTurn is one of the best on the market. It provides the shortest programming time when producing individual parts and small series.

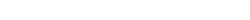

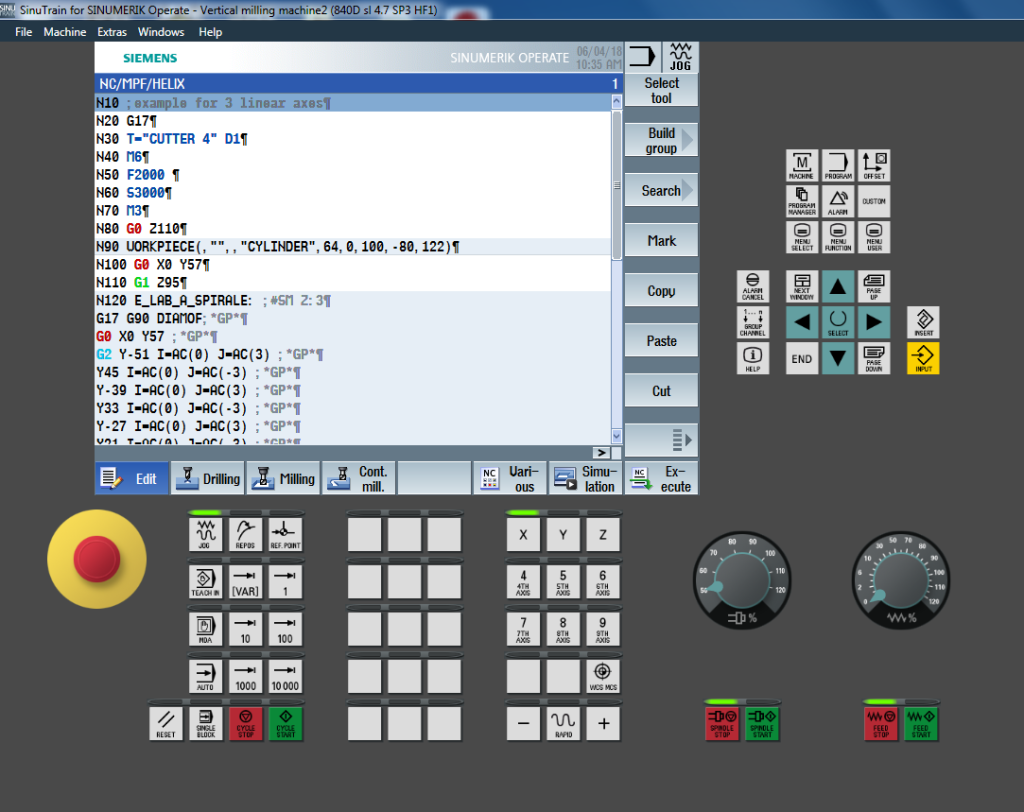

Sinumerik 840D sl

With its premium SINUMERIK 840D sl CNC, Siemens Machine Tool Systems can confidently address every important technology in the machine tool market. These include: milling, turning, machining composites, gear hobbing, grinding, nibbling, waterjet, plasma and laser machining. The SINUMERIK 840D sl sets the pace in the market for high-speed 5-axis milling centers. The same is true for turning centers with B-axis and highly productive multi-spindle applications. The range of applications that the SINUMERIK 840D sl addresses doesn’t just stop where a classic machine tool ends: robotic handling/machining, transfer lines, rotary indexing machines, with or without the tool. The SINUMERIK 840D sl clearly proves its performance wherever precise and dynamic path motion is required.

Sinumerik ONE

Like its predecessor, the SINUMERIK ONE can address every technology in the machine tool market while also covering most other applications as well. With SINUMERIK ONE, Siemens has created the first CNC control system worldwide, which was developed from the ground up to master the challenges of digital transformation in the machine tool industry. This results in a paradigm change: The digital twin becomes an integral component of the control system and the command variable for taking real action. Machining processes and machine behavior can be simulated in detail in conditions close to those met in reality.