CNC Retrofits

As an Integrator with over 38 years of experience in the machine tool industry, we believe that to properly retrofit a machine tool with a new CNC system, the application and specific customer requirements must first be considered.

By carefully evaluating the specific needs of each application, we develop comprehensive turn-key retrofit solutions that leave our customers with little to do when it comes to retrofitting their machines.

PROJECT EVALUATION EXPLAINED

During the evaluation process we look at key characteristics of the machine tool. Such things as machine type, number of servo axes, number of spindles, motor nameplate information, type of feedback, motor cable lengths, and machine auxiliary functions are key in determining the correct solution. We also look at the specific control features the customer must have to do their machining functions. These features may be canned cycles, macro programs, rigid tapping, threading, spindle orientation, and C-axis functionality, to name a few.

We also look to see if the customer has any mechanical and/or electrical information for the machine. Having electrical schematics can help minimize initial cost to the customer. Digital pictures of the overall machine, the electrical cabinet (inside and out), and the operator station help us determine the machine layout and the design required for the solution.

It is extremely important to review the condition of a machine both mechanically and electrically when evaluating it for retrofit. Wear of various mechanical components can lead to poor performance of the control system. Such things as wear in the ways, ballscrew components, and spindle bearings need to be addressed during the control retrofit process. Additionally, components on the machine that are not working properly such as lube systems, field indicators (switches, etc.) and hydraulic leaks can all cause the machine capability to deteriorate. In some cases a good control system can work around worn components for a while, but in most cases this is not desirable. Also evaluated is the condition of electrical components such as field devices, enclosures, and cooling systems. This evaluation determines if existing components can be reused or if they need to be replaced.

The customer’s specific use of their machine determines the application requirements. In some cases a customer may want to add material handling, remote access, supervisory information, or additional control features. It is important to discuss the customer’s application requirements in detail during the evaluation stage so that all control options needed are reflected in the quotation.

The customer knows all too well the shortcomings of their outdated control system. These shortcomings can increase operating and support costs and increase machine down-time; which ultimately cuts into profits. Such things as control speed, program memory, internet access, and on board programming can all effect the cost of manufacturing. Newer control platforms allow the customer to address areas such as these and many more.

The project timeline is important for a number of reasons. The customer may need to know how long the machine will be out of service during installation or how long the overall project will take to complete. The timeline will also help determine how part shipments, system build, and installation effect the customer directly. Medium size retrofit projects on average take 8-12 weeks from order placement to completion of the project. This can vary based on the size and complexity of the machine. In some cases emergency retrofits can be performed within a couple weeks if parts are in stock and the integrator’s schedule is open.

A customer’s available budget or what they are willing to spend will in many cases determine the type of retrofit they have done. Cost can increase substantially if a customer wants more than just the control replaced. Such things as upgrades to magnetic, drives, and enclosures can as much as double project costs. Additional things such as special control features and mechanical work can also effect the overall project cost.

OUR TURN-KEY CNC RETROFITS INCLUDE

- Design

- Project Management

- Electrical Schematic Development

- Bill of materials

- Source code development

- Packaging

- Configuration/Setup

- Power-up checkout

- Commissioning / Integration

- Qualification

- Final documentation

Siemens 828D: Bridgeport Series I Knee Mill CNC Conversion

Siemens 840D sl: WMW BMT-125 Horizontal Boring Mill

Stirk Planer Mill with NUM Flexium CNC

Siemens 808D: Fellows Shaper

Siemens 840D Analog: 5-Axis Router

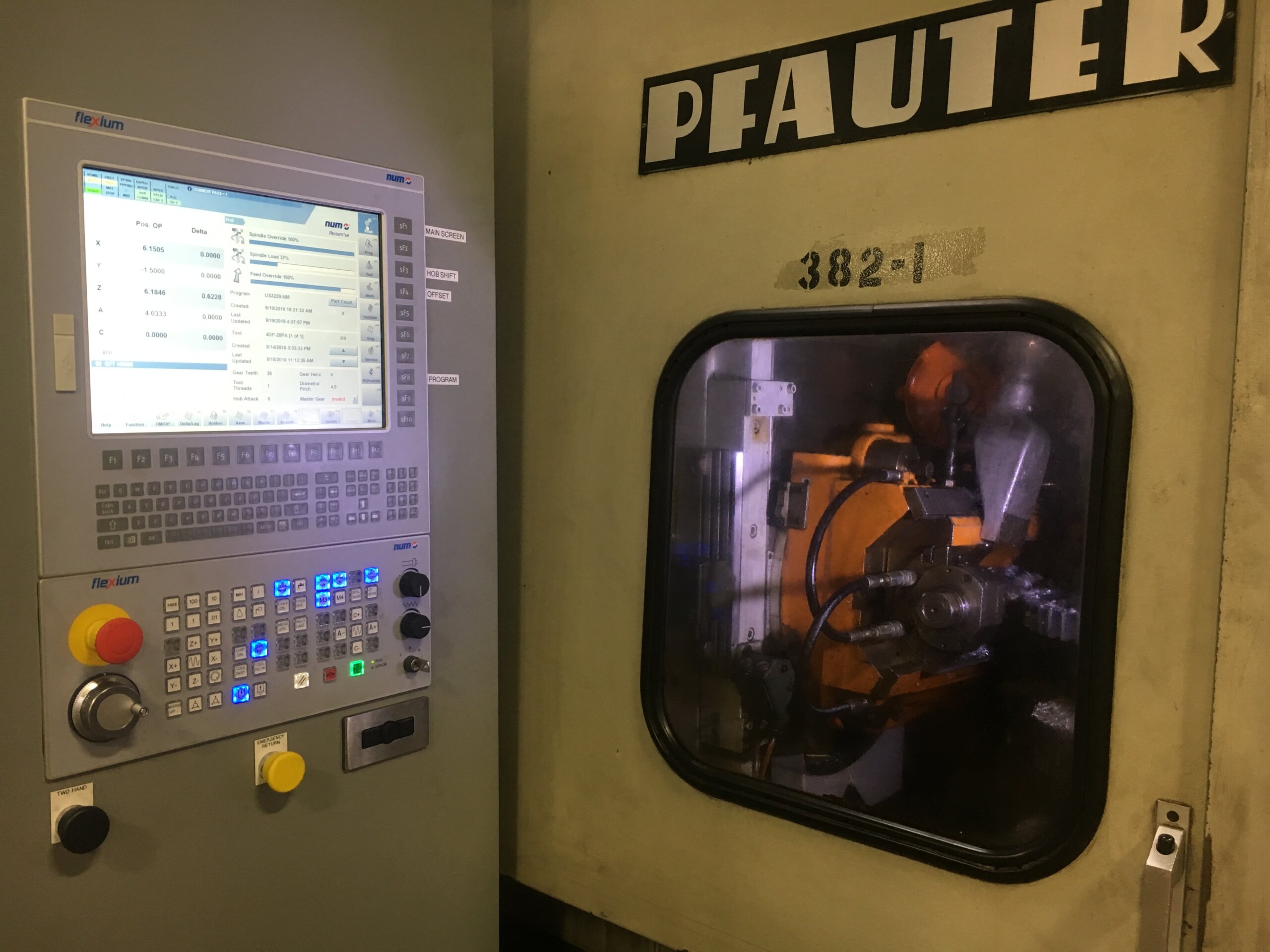

PFauter Gear Hobber with NUM Flexium CNC

Gray Planer Mill with NUM CNC

Siemens 808D Advanced: OM VTL CNC Retrofit Conversion

Siemens 828D: Shinx ZXS2 CNC Router (4 Spindle)

Siemens 828D: Fryer MB14Q Tool Room Bed Mill

Siemens 828D: Toshiba BTD-11B Horizontal Boring Mill

Siemens 828D: Cincinnati 5H-100 Horizontal Boring Mill

Now Offering Siemens 808D CNC Retrofit Kits

A Solution Even Small Shops Can Afford!

We are proud to offer not only the lowest cost Siemens CNC Retrofit Kits in the industry, but the best value low-cost CNC kits available. Our Siemens CNC Kits are perfect for small to mid-size mills, lathes, routers, and grinders. With the 808D Advanced Retrofit Kit you can run up to 4 interpolating axes plus a spindle and up to 2 positioning/indexing axes.

Kits are available with servo motors up to 40 Nm and can be ordered in three configurations: Hardware Only (Siemens hardware, starter prints, and PLC code), Pre-built Enclosure with Operator Pendant, and Pre-built Standalone Console.

All of our package configurations include a CNC display/control (PPU), machine control panel (MCP), and drives & servo motors with cable sets. Our Pre-Built Packages also include: enclosures, control components, power supplies, control transformer, output and safety relays, lockable rotary disconnect, resettable breakers for circuit protection, multi-cable thru gland, and control drawings.

A commissioning manual is also included with our DIY CNC Kits.

Pre-built 3-Axes Siemens 808D CNC Kits start at only $17,000.

If you are interested in the Siemens 808D or Siemens 808D ADVANCED CNC Kits, please contact us. We would love to discuss your application and answer any questions you may have.