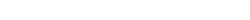

The planer milling machine has multiple types: Gantry verses open side, traditional (single tool) verse rotary spindle, and multi-head (top and sides) verses single head and many others. Each type can be control via a relay system, a PLC, or a CNC control. Both planer milling machine retrofits featured in this article were PLC upgrades. The first machine shown is a Giddings & Lewis Open Side Planer and the second is a Giddings & Lewis Single-Head Gantry Type Planer.

When doing these types of upgrades it is important to first determine what type of machine you have, and what components can be reused or replaced. Typically, relay and PLC machines are upgraded with a new PLC and variable frequency drives (VFDs). In some rare cases a customer may want to update the machine to a full or partial CNC which requires some mechanical modifications. In the case of machines that are already CNC a customer will usually want to upgrade the CNC, motors, drives, and some of the magnetics, though in some cases older drives and motors can be reused.

As an integrator, we have years of experience in retrofitting each type of planer milling machine. This article will review the type of work done on these machines in order to bring them back to high-end working order.

Planer Milling Machine PLC Upgrades

There are vast improvement when upgrading relay or old PLC machines. Many issues with old machines with these control systems can be tied to obsolete parts and electronic failure of components. MCI uses the most up to date technology in order increase uptime and machine ease of use. This will enable the machines to be in service for many more years.

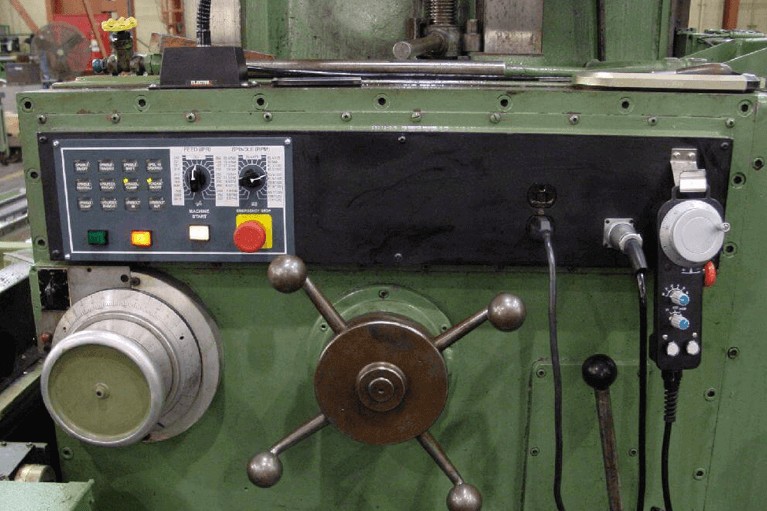

Retrofit Components in the G&L Open Side Planer

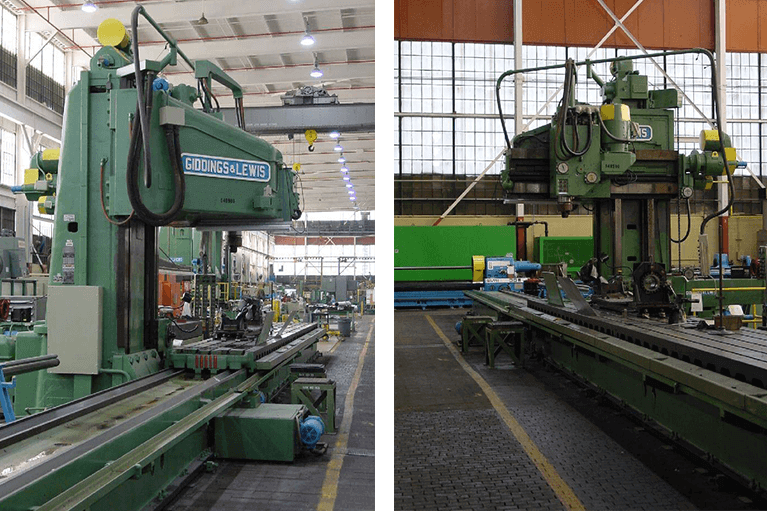

New Electrical Cabinet

- Magnetics/Starters

- Power distribution

- Power supplies

- Line Reactors

- Digital DC drives

- Interface relays

- PLC control

- IO system

- Operator interface and controls

- Isolation transformer

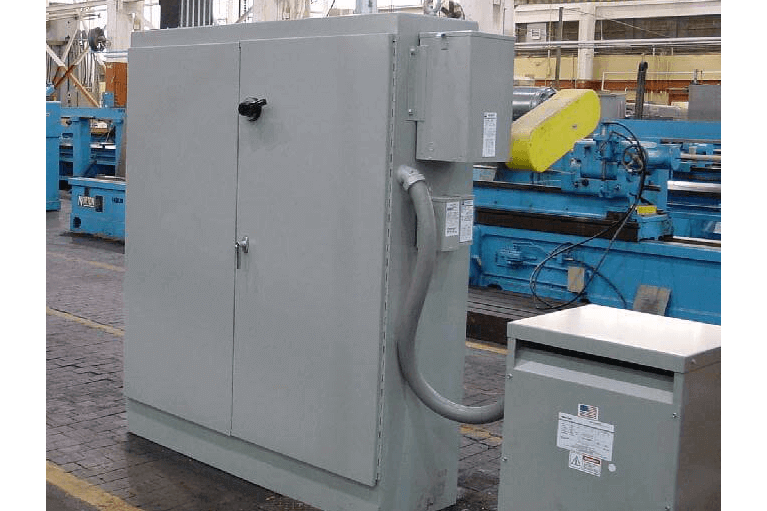

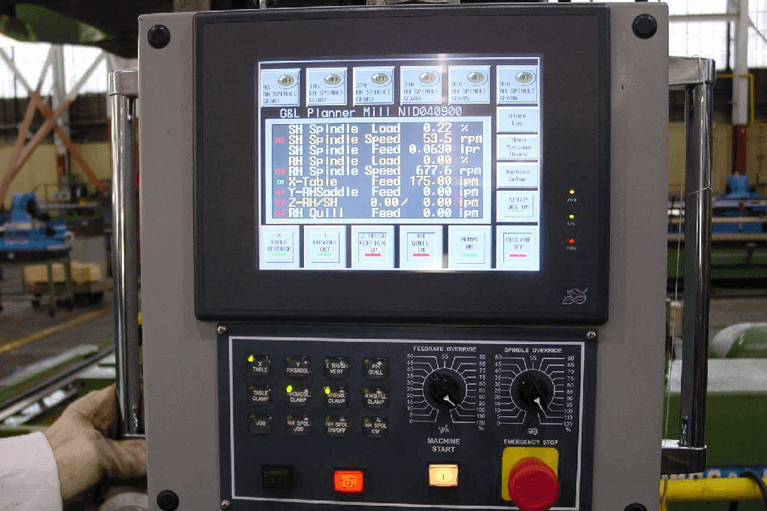

New Operator Station

- 10” Operator display

- Machine Tool Builder Panel (MTBP)

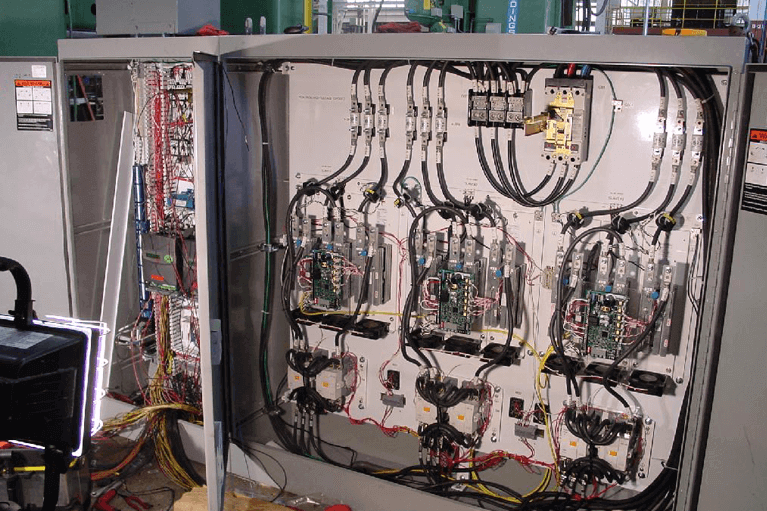

G&L Gantry Planer Milling Machine PLC Upgrade:

The second machine pictured is a gantry style planer mill with relay controls and an Allis Chalmers control system for the motors. This machine had 3 planing heads with AC motors for spindles. The table and positioning of the head was done via DC motors. The following components were included in the retrofit:

New Electrical Cabinet

- Magnetics/Starters

- Power distribution

- Power supplies

- Line Reactors

- Digital DC drives

- Interface relays

- PLC control

- IO system

- (3) AC softstarts for spindle control

- Operator interface and controls

- Isolation transformer

New Operator Station

- 10” Operator display

- Machine Tool Builder Panel (MTBP)

Benefits of a Planer Milling Machine Retrofit:

- Short setup times

- Minimal operator training

- New panel, PLC or CNC, and IO components (Drives and motors on CNC retrofits)

- The addition of a portable handpulse generator pendant for CNC retrofits

- RS274 programming standard (G-Code) allowing for no limitation to programming flexibility

- Smooth and high speed machine operation

- Full system documentation with new prints developed for system retrofit

- Unlimited program storage (for CNC retrofits)

- Easily networkable through PLC or PC front end.

- No homing required on systems where drives and motors where replaced

- 2 year warranty on all CNC system components

- Remote access to control system allows for remote support