Siemens 840D sl Analog: Bostomatic 400 Machining Center CNC Retrofit

This Bostomatic 400 Mill was owned by MCI until a customer requested if we could modify it for their additive process. This required stripping many components off the machine including the spindle, spindle motor, counterbalance, and the old enclosure. The customer’s additive application demanded a high-performance control with very fast update times. Because of these requirements, the Siemens 840D sl was chosen.

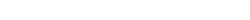

The new system included an 840D sl NCU 710.3 with a TOP 1500 15.6” touch screen display and an MCP 398C machine control panel. In order to use the Bostomatic 400’s original motors (Control-Only Retrofit), third-party GSK analog drives were used in conjunction with a Siemens ADI4 module, then connected to the NCU via a Profibus connection. The entire system fit in a small 24x36x12 enclosure that was attached to the back of the machine. The TOP 1500 display and MCP 393C were placed in a new operator station along with a wireless hand pulse generator (HPG).

The customer’s application required large part programs, so the available memory on the control was expanded to its maximum of 4GB. The additive application also required the use of an ET200SP fast IO module, which would output the machine’s path velocity synchronously as an analog signal, updating every 2ms. This enabled the customer to easily integrate the laser used in their additive process and meet their performance specifications.