On this project we were contacted by an end user in the wood industry. This user manufactures various types of wood panels and door products. They purchased a used BP-10 Weeke CNC Router from an auction. This router had an older NUM 750 control that had lost its memory due to a low battery. The customer looked at various options and decided to retrofit the machine. At this point they contacted us for a possible CNC Retrofit solution.

The NUM 750 CNC system was capable of machining complex shapes, but had various limitations:

- The control system was outdated

- Setup time was lengthy and difficult

- Operator training was difficult and time consuming

- Replacement part were hard to come by and expensive

- The customer was unable to add custom application components- clamping, fixtures, etc.

- Part setup was limited to screen entry fields

- Memory size was limited

- Networking ability was limited

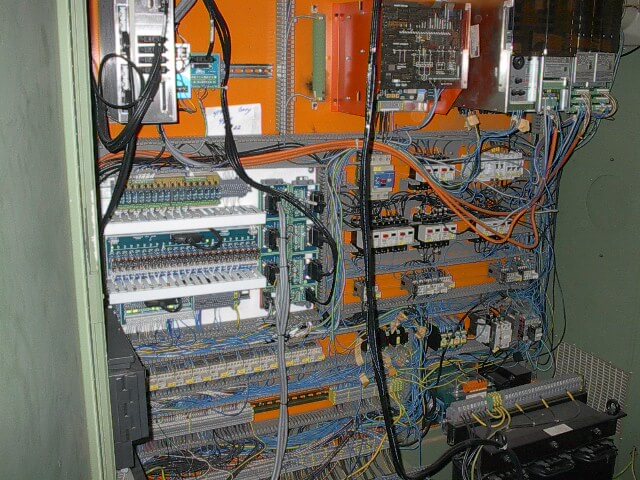

- Documentation non-existent

Based on the current systems limitations we set out to provide the customer with a solution that would address all the short comings of the current CNC system. Our solution consisted of a turn-key CNC Retrofit using a New (at that point in time) NUM 1040W CNC system. This particular CNC control allowed us to reuse the customer’s existing Indramat servo drives and the original control cabinet.

The new NUM CNC system allowed us to provide a high-end CNC Retrofit solution for the Weeke CNC Router that boasted the following enhancements:

- Short setup times

- Minimal operator training

- New panel and IO components

- The addition of a portable handpulse generator pendant for manual positioning and machining

- RS274 programming standard (G-Code) allowing for no limitation to programming flexibility

- Smooth/high speed machine operation

- The addition of an operator’s panel on a pendant arm close to work envelope

- Machine customization such as fixturing control, custom Mcodes, and special machine functions

- A higher level of safety in two sided operation

- Full system documentation with new prints developed for new CNC System

- Unlimited program storage & drip feed

- Easily networkable through PC front end. Industrial PC front end with Flash memory

- Custom macros to meet customer requirements

All of the control engineering and sub-panel build was done off site. When the CNC Retrofit package for the Weeke CNC Router was complete, a time convenient for the installation was set. The package was then delivered to the customer site and the installation started. Installing the new subpanel, CNC Control, Operator’s Station, Pendant arm, and the wiring in the magnetics cabinet took about two days. When this work was completed we began powering up the machine and checking it for functionality. We worked with customer personnel during this phase of the project so they would become familiar with the new control and comfortable operating the machine from the new HMI. Additionally, we supplied part program training during the integration phase.

At MasterControls we develop solutions with the future in mind. We take a systematic approach to developing our machine logic and machine functions, which allows our code to be reused on new applications. This approach not only allows us to finish our projects on time, but gives our customers assurance that our code has been tested for reliability time and time again.

We have a CNC Retrofit Solution for your CNC Router. Contact Us for a quote on a solution for your specific application.