Modul Hobber CNC Retrofit

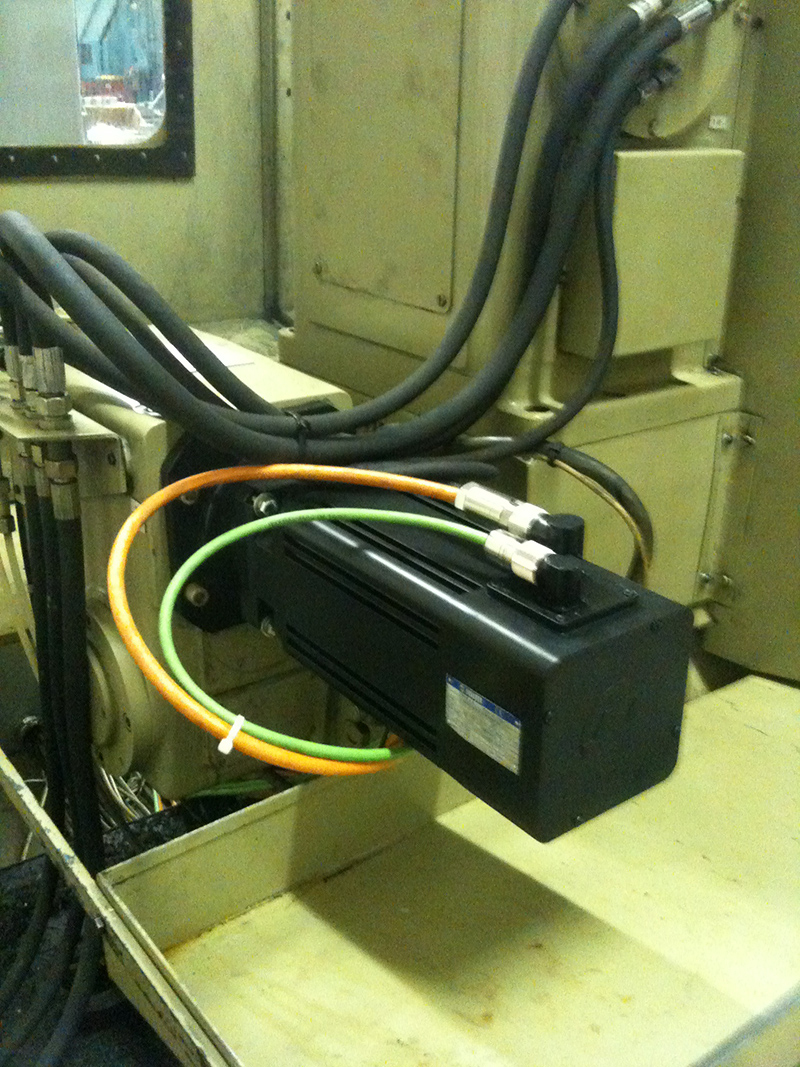

The Modul Hobber is a 3 axis hobber with “change gears”. Each axis has Acme screws instead of ballscrews. The customer’s existing control stopped working, so they asked MasterControls if the machine could be saved. MasterControls designed a solution that gave the customer more flexibility and minimized the overall cost. The design kept the existing “change gears” in place, but utilized CNC technology for different cycle motion profiles. The X (infeed) and Z (longitudinal) motors were replaced with servos in addition to the hob shift motor (Y). The main drive motor was then controlled with a variable frequency drive to set hob and table speed. MasterControls wrote G-code programs to allow the user to enter variables to change cycle positions, feeds, and speeds. The customer could also create their own programs if needed. The customer was able to increase productivity, simplify setup, and add flexibility to program profiles. This configuration can be adapted to any manual hobbing machine without the expense of full CNC or Hobbing software.

MasterControls used the NUM Axium control with digital servo drives on this project. They also provided a complete enclosure with magnetics. All the motors were absolute so that the customer did not have to home the machine. MasterControls also offers this same configuration in the Siemens 808D control.